DeWeyl Tool was started in 1969 in California, USA as an original equipment manufacturer for ultrasonic bonding tools. DeWeyl was the first to produce ceramic tip wedge tools with the longest lasting tool life. Other tool materials such as titanium and tungsten carbide are also made by DeWeyl and are used in bonding aluminum, gold, copper, and platinum wires.

DeWeyl Tool supplies tools to major bonding equipment manufacturers including F&K Delvotec, Hesse, K&S, TPT and West-Bond and others.

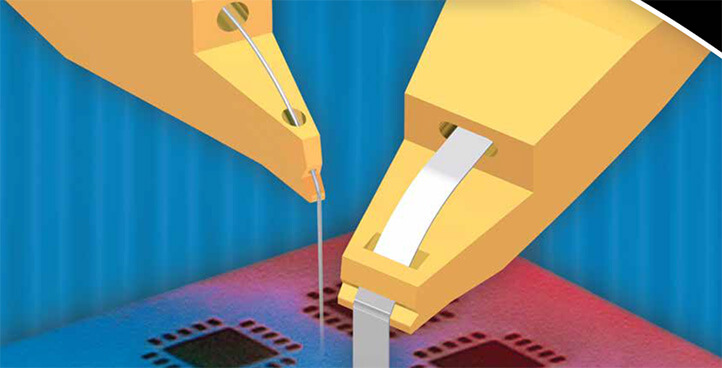

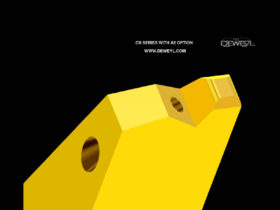

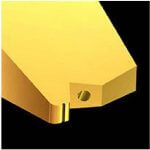

With more than 50 years of wedge bonding experience, DeWeyl has developed many different tool designs for wires, ribbons and tab bonding.

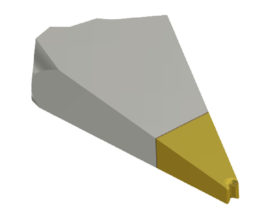

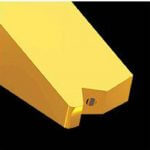

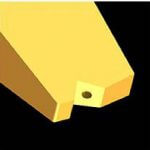

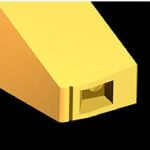

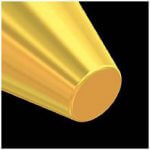

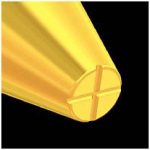

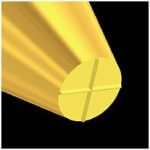

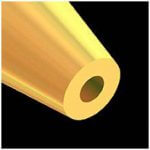

The Ceramic Advantage

- WHY CERAMIC? – DeWeyl Tool developed the industry’s first Ceramic tip bonding wedge, because common bonding wedge materials such as Tungsten Carbide and Titanium exhibited specific performance limitations.

- BENEFITS – Our Ceramic tip wedge offers impressive benefits for both gold wire, aluminum wire and gold ribbon ultrasonic applications. It also has a proven track record on both production and R&D products. Here are some of the reported advantages when using our Ceramic tip wedge:

✔Increased Bond Adhesion

✔Increased Pull Test Results

✔Ultrasonic Output Reduction

✔Extended Wedge Life

✔Improved Bond Definition

✔Gold Bonding at Ambient Temperatures

✔Improved Production Yields

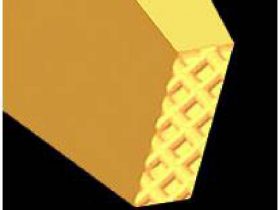

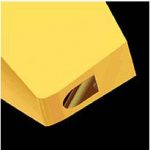

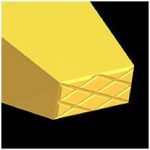

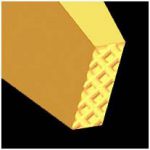

- ULTRASONIC EFFICIENCY – One of the most significant benefits of the DeWeyl Ceramic wedge is the excellent tool to wire interface. The ideal ultrasonic bonding wedge allows for zero tool slippage while in contact with the wire and during the application of ultrasonic energy. If the tool has zero slippage then the ultrasonic transfer of energy is operating at 100%. This is the value of the Ceramic wedge. The naturally porous structure of the Ceramic offers a surface texture that couples with the wire giving optimum ultrasonic transfer. This efficiency in transfer allows for a reduction in ultrasonic power and time levels, which results in a superb tool-to-wire interface and thus efficient ultrasonic energy transfer. Difficult applications due to low bonding temperature or contaminated bond surfaces are made easier with the use of the Ceramic tool.

- ECONOMICAL – The standard angle feed Ceramic wedge (non vertical feed) costs only 8% more than the cost of titanium. And the cost of a vertical feed Ceramic tool is only 18% more expensive than the cost of titanium. The additional cost for ceramic becomes very economical when DeWeyl customers understand that the life expectancy of Ceramic is 2-3 times greater than other available materials. The net cost per bond thus is significantly lower with the Ceramic wedge.

Contact us for more information.